KT-2513PA

Features

Diverse Printheads Permutation Modes

CMYK/CMYK+W+V/CMYK LC LM+W+V Support 8 spot colors-CMYK+W+CMYK/2 Rows/4 Rows CMYK custom solutions

Machine Features

1.Head plate can be arranged in 4 rows(Ricoh G5、G6、G5i) , suppont faster printing and more application solution.

2.42.5mm aeronautical aluminum printing platform,which surface is treated with hard oxidation.

High hardness and corrosion resistance. The square bearing weight 120 kilograms.

3.Automatic lifting of carriage and automatic height measurement with mechanical probe. Support up to 125mm thickness print media.

4.Plasma electrostatic eliminator can effectively solve the splashed ink generated by the static and improve the stability of printing.

Product Advantages

Printing control system and RIP software

It installed UMC printing control system which is the most stable ink jet printing control and printer hardware control. It matched USA PHOTOPRINT RIP software that made image more colorful, input image compared with real image attached over 98%.

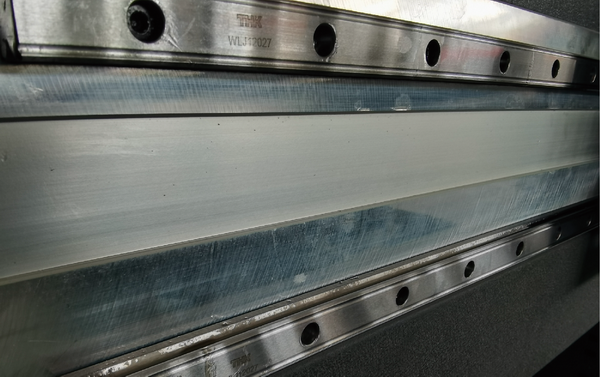

Japan THK mute guide rail

X printing direction with two THK mute guide rail, high resolution, lower noise, stand wear and tear so that ensure carriage moving stable. Z axle with double guide rail to ensure carriage lift balance.

Japan fuji servo system

Four servo motor(including X,Y,Z axle) high resolution running, X direction 750W Japan fuji gear motor without belt and pulley to transform that avoid the deviation brought by pulley transform power. Y direction with two 400W JAPAN FUJI servo motor, double driver with bigger power and running smoother. Z axle servo motor, double guide rail and automatic height measure that no need to make bidirection calibration parameters when print different thickness media.

Electrostatic eliminator

During UV printing, electrostatic eliminator close the interface of the media, the high voltage corona discharge at the tip ionizes the air into a large number of positive and negative ion static electricity, which is neutralized with the static electricity on the surface of the material to avoid the flying ink phenomenon caused by static electricity.

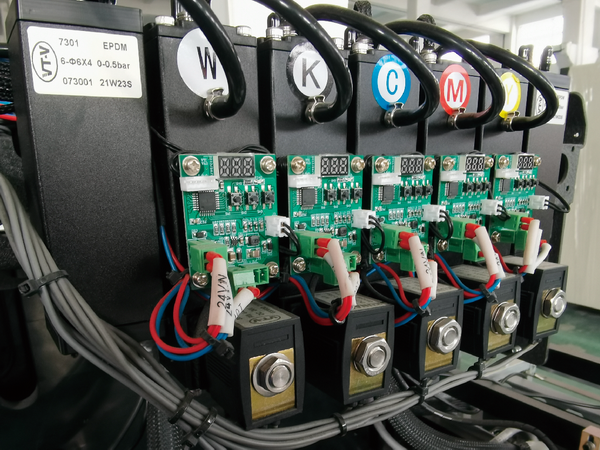

Sub ink tank

Anti-corrosion and heating & circulatory function ensure ink temperature meets its requirement, when at low temperature environment won’t influence ink smooth and printing effect.

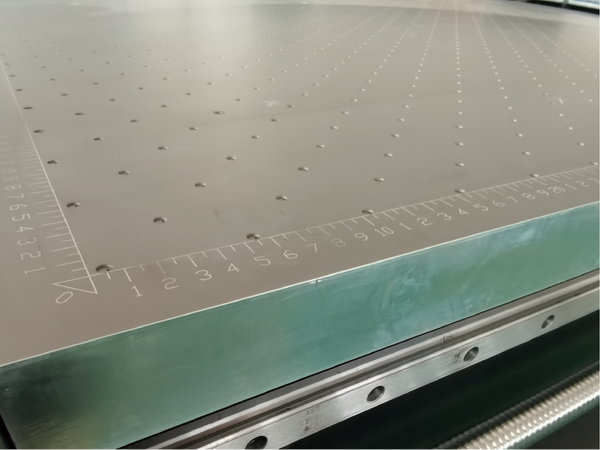

Hard oxidation adsorption platform

Carbon alloy honeycomb suction, surface hardening treatment, absorption UV light does not reflect protection nozzle, not easy to scratch, XY two-way scale convenient operation, printing platform XY two-way pneumatic zero limit, it can feeding accurately, equipped with 2.2 kW suction turbine, four electronic partition control, no need manual switch valve, ensure the adsorption of materials on the platform.

Application

Technical Parameters

|

Printer Model |

KT-2513PA |

Operation System | Windows7/10 64 bits (Flagship/Professional Version) | ||||

| Printhead |

Ricoh G5 (2-9) / G6 (2-9) / G5i (1-6) |

Computer Configuration | Hard disk: SATA500/Hard disk format: NTFS/CPU: Inter i5/i7RAM: 8G-16G | ||||

|

Printing Speed |

High Resolution Mode | 8Pass | 8㎡/h Group | 11㎡/h Group | 5㎡/h Group | Drying | LED-UV lamp curing |

| Production Mode | 6Pass | 12㎡/h | 18㎡/h | 7㎡/h | Media Type | All advertising, decoration materials, metal plate, glasseswood material, plastic etc | |

| Sketch Mode | 4Pass | 16㎡/h | 22㎡/h | 10㎡/h | Maximum Power | 7000W (Including suction fan power 3000W) | |

| Ink | Type | Imported environment-friendly UV ink (Soft/Neutral/Hard) | Operation Environment | Humidity: 40%-70% Temperature: 20-30℃ | |||

| Color | M / Y / C / K / LM / LC / White / Varnish | Power Supply | AC220V±10% 50HZ 7KW | ||||

| Printing Area | 2500mm x 1300mm | N.W | 1600kg | ||||

| Printing Thickness | 125mm | Machine Size | L*W*H: 4600*2193*1550mm | ||||

| RIP Software | PHOcenterRINT | Package Size | L*W*H: 4780*2270*1850mm | ||||

| Image Format | TIFF /JPG /EPS /PDF | AI Visual Positioning (Optional) | Full-frame Ai visual positioning printing system | ||||

| Data Transfer | YCP /IP Network Interface | ||||||